Cigarette Inner Lining Paper: This is the paper lining the inside of cigarette packs, providing a certain degree of moisture resistance and aroma retention for the cigarettes.

Nowadays, environmental sustainability and safety have become the primary considerations for consumers when selecting products. Currently, the mainstream inner lining paper products in the cigarette market are aluminum foil laminated paper or metallized paper, which pose potential safety risks due to metal residues and also contribute to environmental pollution. In response to national low-carbon initiatives, domestic and international tobacco companies are actively collaborating with enterprises to develop green, non-aluminum inner lining paper, with the intention of replacing traditional aluminum foil inner lining paper with these eco-friendly alternatives.

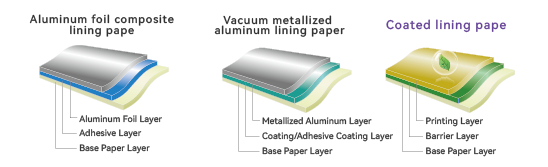

1、Structural Comparison of Different Inner Lining Paper Products

2、Compared With Traditional Products

| Aluminum foil composite lining paper | Vacuum metallized aluminum lining paper | Coated lining paper | |

| Adv. |

|

|

|

| Disadv |

|

|

|

3、 Key Performance Evaluation Criteria for Non-Aluminum Inner Lining Paper

Water Vapor Transmission Rate: Before embossing, it should be less than 300 g/m²·day; after embossing, it should range between 500-800 g/m²·day.

Machine Adaptability: The inner lining paper must meet machine adaptability requirements, enabling mass production.

Health and Safety Standards: The 24 solvent residue tests must comply with national tobacco regulations.

4、 Key Economic Evaluation Criteria

The market capacity for cigarette inner lining paper in China is approximately 80,000 tons, with over 90% currently being aluminum-containing inner lining paper. The global market for cigarette packaging materials is vast, with annual production reaching hundreds of thousands to millions of tons. As a green packaging material, coated inner lining paper aligns with the development trends of cigarette packaging both domestically and internationally.

-

Shiner Presents at World Tobacco Middle East 2025

On November 11, 2025, our international marketing team participated in the World Tobacco Middle East 2025 exhibition (Booth T186) in Dubai, engaging in in-depth exchanges with global tobacco industry partners and exploring business opportunities. We also presented Chinese gifts.

2025-11-12

-

Contact Us

Hi-Tech Zone, Hainan, China

Email:zhuhaiyan@shinerinc.com

Tel: +86-0898-6858 1104

Fax:+86-0898-6858 5861