- Tobacco Film

- Recloseable Package

- Laser Holographic Anti-counterfeit Film

- Coated Film

- Positioning Printing Hot Foil Film

- Functional Tobacco BOPP Film

- Environmental Friendly Innerliner

- PLA Tobacco Film

- Filter Tow/ Filter Rod

- Other Tobacco Packages

-

-

Second-generation Automatic Opening

The labels feature a straightforward and uncluttered

design.

The primary materials used are bright silver PET and

matte silver PPET.

The surface tension of the labels must meet specific

criteria (≥42 dyne value).-

¥0.00¥0.00

-

The labels feature a straightforward and uncluttered

design.

The primary materials used are bright silver PET and

matte silver PPET.

The surface tension of the labels must meet specific

criteria (≥42 dyne value).

I. Product Introduction

This product is a proprietary development tailored for automated cigarette packaging, ensuring moisture preservation.

After cigarettes are wrapped by an automated machine, the adhesive label on the packaging works seamlessly with the moisture-preserving inner liner during repeated openings and closings.

This method not only introduces a unique way to package cigarettes but also significantly improves the packaging’s functionality, preserving moisture and fragrance, blocking oxygen and humidity, and maintaining the cigarette’s original flavor.

II. Product Type

|  |

■ Recloseable package of first-generation cigarettes Manual Opening The consumer is able to open and reclose the pack manually. | ■ Recloseable package of second-generation cigarettes Automatic Opening The Label is attached to the hinge lid and opens with the pack providing smart |

Characteristics —— First-generation Manual Opening

The labels feature a straightforward and uncluttered design.

The primary materials used are bright silver PET and matte silver PPET.

The surface tension of the labels must meet specific criteria (≥42 dyne value).

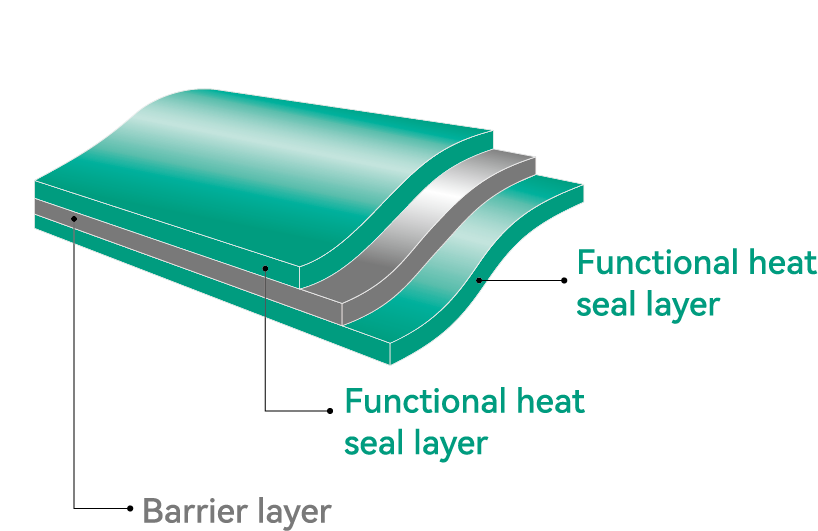

III. Product Structure

■ Recloseable Package – Moisture-preserving Inner Liner

The moisture-preserving inner liner is composed of:

Functional heat seal layer – Functional heat seal layer: An independently developed BOPP material that offers high-speed, low-temperature heat sealing properties and is compatible with printing, holography, and embossing processes.

Printing – Conducted using inside printing techniques with cigarette packaging-grade ink, ensuring an odorless and solvent-free finish.

Lamination – A solvent-free lamination process that is odorless and leaves no solvent residue.

Barrier layer – Aluminum foil material that provides moisture preservation, fragrance retention, and excellent barrier properties against oxygen and water vapor, safeguarding the cigarette’s flavor.

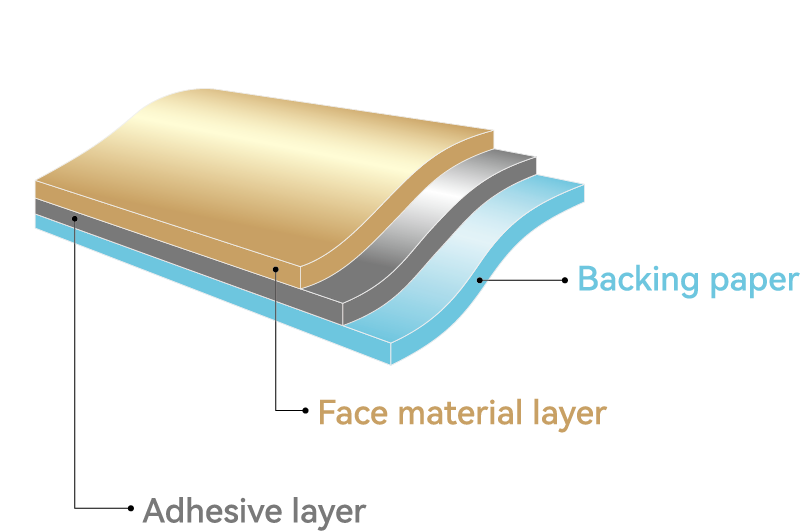

■ Recloseable Package – Adhesive Label

The adhesive label’s structure is as follows:

Face material layer – This layer is carefully selected and processed to ensure that the label’s use and display align with the brand’s design philosophy and enhance the customer experience.

Adhesive layer – It has excellent initial tack and remains unaffected by temperature and humidity. The label can be opened and resealed more than 50 times without noise and leaves no residue.

Backing paper – This can be either glazing paper or PET base paper, depending on the labeling requirements of different equipment.

IV. Product Features

The materials used in the Recloseable Package and Adhesive Label adhere to U.S. FDA and European CE certifications, characterized by low VOC emissions and minimal odor, safeguarding the cigarette’s flavor and ensuring the safety of the packaging process.

This product merges functional utility, brand elevation, packaging safety, and aesthetic appeal, epitomizing a new era of cigarette packaging innovation.

V.Physical Performance Index

■ Recloseable Package – Adhesive label

| SN | Index | Unit | Index |

| 1 | Length | mm | Design value ±0.5 |

| 2 | Widththe | mm | Design value ±0.5 |

| 3 | Thickness | μm | Design value ±2.0 |

| 4 | Number of repeated openings | Times | ≥50 |

| 5 | Color difference (△Eab) | —— | ≤3.0 (same batch, same color, or benchmark standard sample) |

| 6 | Other | —— | The label should be flat, odorless, and free of any residual glue, with no noise during opening. There should be no delamination or residual glue visible at the U-shaped notch. |

■ Recloseable Package – Moisture-preserving Inner Liner(Film Roll)

| SN | Index | Unit | Index | |

| 1 | Appearance | — | The appearance should be clean and flat, with no overlaps, The color should be uniform, and all elements such as hues, oriented. There shouldbe no odor, and there should be no signs of base leakage or oxidation. | |

| 2 | Unit length | mm | Design value ±0.5 | |

| 3 | Unit width | mm | Design value ±0.5 | |

| 4 | Unit thickness | μm | Design value ±3.0 | |

| 5 | Heat seal strength (127℃, 0.1Mpa, 1s) | N/15mm | ≥3.0 | |

| 6 | Friction coefficient (outer/metal) | — | ≤0.3 | |

| 7 | Oxygen transmission rate at 23℃, 0%RH | cc/m²·24h | ≤1.0 | |

| 8 | Water vapor transmission rate at 38℃, 0%RH | g/m²·24h | ≤1.0 | |

| 9 | Core inner diameter | mm | Design value ±0.5 | |

| 10 | Core thickness | mm | ≥6.0 | |

| 11 | Roll length | m | Design value ±3.0 | |

| 12 | Color difference (△Eab) | — | ≤3.0 (same batch, same color, or benchmark standard sample) | |

| 13 | Joint | Joints per roll | Piece/roll | ≤2 |

| Per batch | % | ≤30 | ||

| 14 | Packaging | — | Label the cores and film rolls with an arrow mark to indicate the direction of unwinding, and then seal them. | |

VI. Transportation,Storage and Expiration Date

During transportation, the product should be shielded from rain, moisture, and excessive pressure.

It is crucial not to transport the product alongside toxic, odorous, flammable, or similar hazardous materials.

Storage should occur in a dry, clean, odor-free, and well-ventilated environment.

The product can be stored in an environment with a suitable temperature range of 20-30°C and humidity level of 0-50% relative humidity for up to one year.

Contact Us

Hi-Tech Zone, Hainan, China

Email:zhuhaiyan@shinerinc.com

Tel: +86-0898-6858 1104

Fax:+86-0898-6858 5861