- Tobacco Film

- Recloseable Package

- Laser Holographic Anti-counterfeit Film

- Coated Film

- Positioning Printing Hot Foil Film

- Functional Tobacco BOPP Film

- Environmental Friendly Innerliner

- PLA Tobacco Film

- Filter Tow/ Filter Rod

- Other Tobacco Packages

-

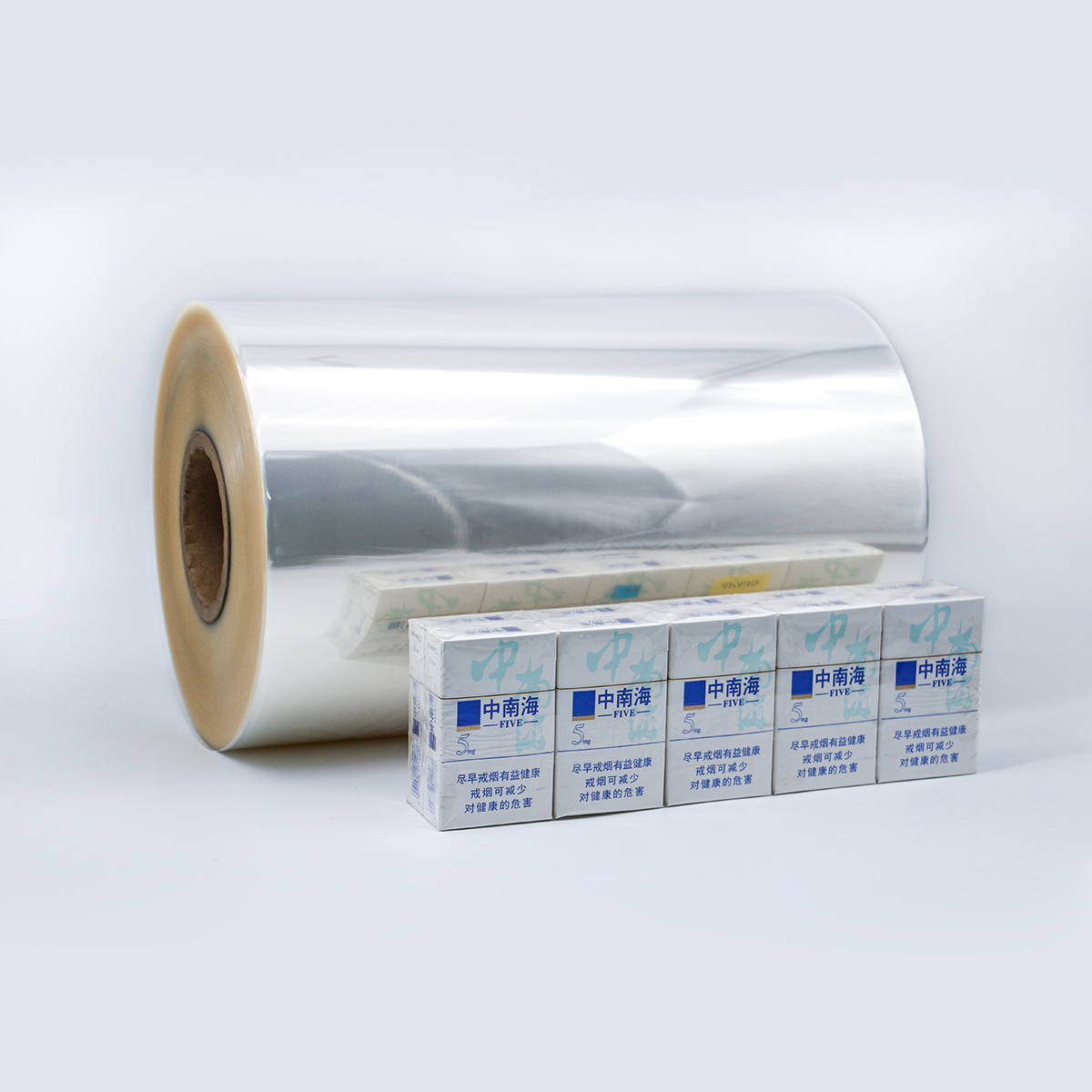

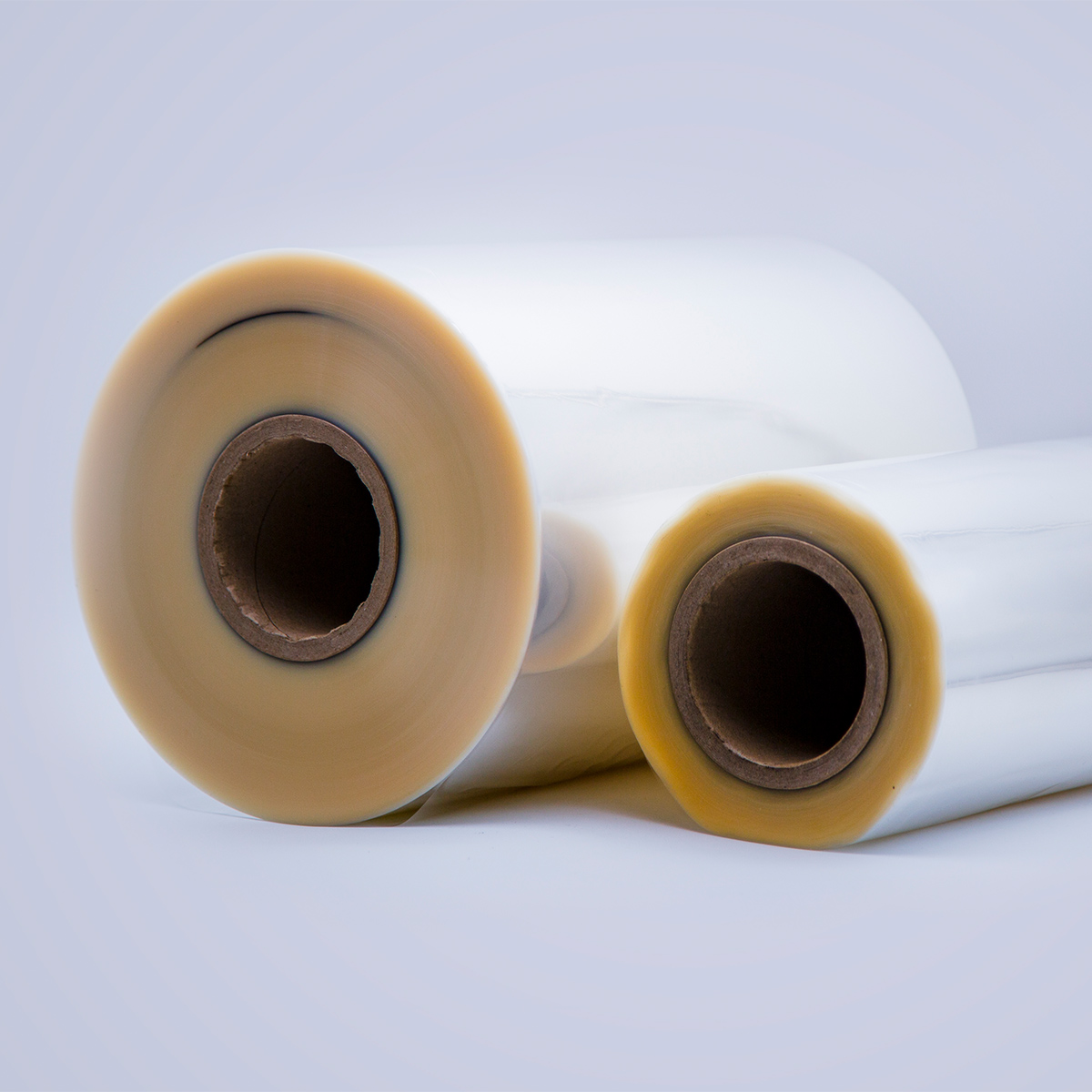

BOPP Naked Wrap Film

CNP

-

¥0.00¥0.00

-

CNP

Product Description

CNP is a functional PP film produced through a three-layer co-extruded biaxially oriented process. This film features two functional layers with characteristics such as ultra-low temperature heat sealing and high-temperature slip properties. It can achieve self-sealing over a wide temperature range and does not stick to conventional BOPP films.

Key Features

Excellent optical and abrasion resistance properties

Moisture, oxygen, and aroma barrier

Good low-temperature heat sealing performance with a wide heat seal range and high heat seal strength

Prevents adhesion to other films within a broad processing temperature range

Applications

Applied to bare packages of products such as cigarettes or cosmetics

Ideal for packaging products that are sensitive to high temperatures

Thickness

21-28 micron

Application Recommentations:

Bottom and side sealing temperature : Recommended temperature 100-120 ℃, depending on the running speed of the packaging equipment and the pressure of the iron;

Tobacco package beauty device: If used, it is recommended that the temperature does not exceed 110℃;

It is recommended that the product be stored in the production plant for 24 hours before use to ensure that the product runs more smoothly and firmly;

The outer surface of the product is highly slip-resistant, while the inner surface is intended to be in contact with the packaged product. Care should be taken to ensure the correct unwinding direction of the film roll during use.

Technical Data

Properties | Unit | Typical Values | Test Standards | ||||

Shiner | National Standard | International | |||||

| Density | g/cm³ | 0.92 | GASTM D1505 | ||||

| Thickness | μm | 21 | Q/SN2 | GB/T6672-86 | |||

| Unit Weight | g/㎡ | 19.74 | |||||

| Tensile Strength | MD | MPa | 180 | Q/SN2 | GB/T1040-92 | ASTM D882 | |

| TD | 296 | ||||||

| Shrinkage | MD | % | 3-8 | Q/SN2 | GB/T12026-89 | ASTM D1204-89 | |

| TD | 3-8 | ||||||

| Elongation at Break | MD | % | 55 | Q/SN2 | GB/T1040-92 | ASTM D882 | |

| TD | 170 | ||||||

| Young's Modulus | MD | N/m㎡ | 2400 | Q/SN2 | ASTM D882 | ||

| TD | |||||||

Heat-seal Strength | TD | N/15mm | 3.5 | Q/SN2 | ZBY 28004 | ASTM F88-94 | |

| Heat-seal Temperature | ℃ | 100~120 | Q/SN2 | ZBY 28004 | ASTM F88-94 | ||

| Coefficient of Friction (film/film) | 0.15 | Q/SN2 | GB/T10006-88 | ASTMD1894-93 | |||

| Haze | % | 1.5 | Q/SN2 | GB2410-80 | ASTMD1003-95 | ||

| Gloss(45°) | % | 93 | Q/SN2 | GB8807-88 | ASTM D2457 | ||

| Water Vapor Transmission Rate | g/㎡/24h | 4.0 | GB1037-88 | ASTM F1249-90 23℃ 85%RH | |||

Note: The performance index in the table is the typical value of the product, not the guaranteed value, for reference only, the specific index is subject to the contract.

Contact Us

Hi-Tech Zone, Hainan, China

Email:zhuhaiyan@shinerinc.com

Tel: +86-0898-6858 1104

Fax:+86-0898-6858 5861